What are the main impacts of media containing solid particles on the design solutions for vertical turbine pumps?

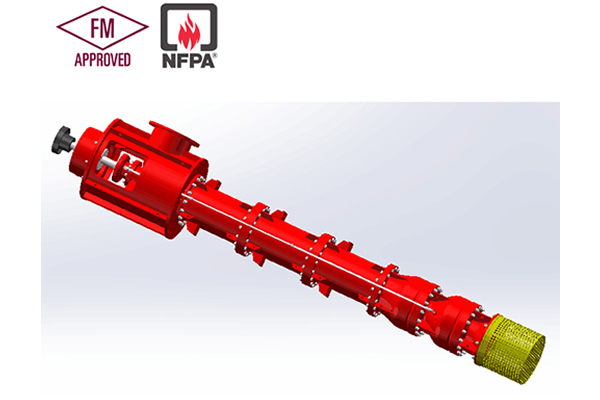

The vertical turbine pump is a critical machine used for pumping out sub-surface water into structures, separating it from the surrounding soil. These pumps are typically used in residential homes, farms and factories. But when the water they pump contains solid particles, it makes the design of these pumps more difficult. This article examines the impact of solid particles on vertical turbine pump design.

Vertical turbine pumps are often designed to handle water atop of oil and gas wells.

It can be challenging to develop vertical turbine pumps capable of transporting water with solid particles. Hard particles can wear out the pump components, and hence breakage may be more frequent and need repair. This vertical turbine pump takes money and time from the owners. Sometimes it allows you to create newer designs and reduce solid particle problems.

Handling Solid Particles in Pump Design

If vertical turbine pumps are going to be used in water that has solid particles, engineers must carefully consider what size and shape the particle will be. Tiny particles can become lodged in the spinning parts of the pump, causing clogs. Larger particles can damage the pump. By learning more about how these grains behave, engineers can look for ways to improve designs.

The Impact of Different Materials on Pump Functionality

What is being pumped will affect how well vertical turbine pumps operate. The performance of the pump can be affected by other solids—such as sand and gravel. For instance, pumps designed to work with sandy water may perform dismally when faced with larger rocks or debris. Understanding how varying materials affect the performance of the pump allows engineers to develop better and more efficient designs.

Repurposing Design Concepts for Rigid Particles

Engineers have to come up with different concepts in terms of design to vertical turbine propeller pump handle solid particles present in the water. They need to ensure that the pump will not be damaged or clogged by these particles. This could involve the use of special materials that resist wear and lack of screens that would keep large particles out of the pump. Resources. By altering their designs, engineers can also produce more reliable and longer-lasting vertical turbine pumps.

Do not underestimate the importance of analyzing the material.

Evaluating the characteristics of the fluid being pumped is critical to the optimal vertical turbine pump designs. Engineers gain a deeper understanding of pump material composition, allowing them to tailor the pump to their needs and better understand what challenges they might face once the pump is in operation. This knowledge allows them to design submersible vertical turbine pump pumps capable of handling the material’s needs. Ultimately, the material analyzed is crucial to determining how to optimize vertical turbine pumps and with what solid particles in order ensure they operate more efficiently.

To sum up, there are opportunities as well as challenges faced by engineers while designing vertical turbine pumps for solid particle solid pumpable materials. Others are done by modifying ideas on the design of the pump, analyzing the materials, studying how solid materials affect pump performance or problems caused by solid materials, and other studies filled the gap with the problem. Designed and maintained properly, vertical turbine pumps are resistant to solids and can continue to yield dependable water moving solutions for a variety of applications.

Comments

Post a Comment