What is the impact of impeller clearance optimization on the efficiency improvement of submersible vertical turbine pumps?

What is Impeller Clearance?

If impeller clearance sounds like an abstract concept, it actually is even easier to grasp. A submersible vertical turbine pump consists of an impeller, which serves in the same role you would associate with a heart, hence it is a very critical component. That section spins, a part pulling water up from the deep underground, the other pushing it all the way up to the surface to be used. How the impeller works is fundamental to the pump performing its task.

THE IMPORTANCE OF IMPELLER CLEARANCE

The pump works because when the impeller spins, pressure is created. The impeller is the rotating element of a pump, and it's that space between the impeller and the pump casing which is called impeller clearance. Clearance is therefore critical to enabling the pump perform effectively. If the gap is too small the pump may have a hard time pumping water. But, if the clearance is too big, it can also be a problem. The double impeller centrifugal pump cannot function properly, causing energy and time waste.

What Is the Effect of Impeller Clearance on Pump Performance?

Impeller clearance optimization refers to an appropriate fitting of space between impeller & pump casing. It is a significant factor in how efficient the pump will be. These are qualified performance variables and they allow water flowing into the pump to be as easy and efficient as possible when impeller clearance is adjusted exactly. Not only does this save energy, it also causes less wear on the pump, which is what everyone wants. If water is needed and a functional pump is available, it can save resources.

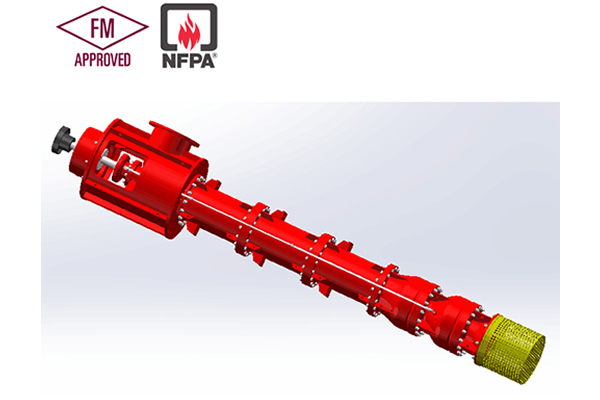

Impeller clearance optimization block diagram

Energy efficiently One of the most important advantages of optimizing impeller clearance is that helps the pump to save energy. If the pump runs efficiently, it uses less electricity to do the same amount of work. This matters, for a couple reasons, including the fact that it is good for the planet, in terms of reducing electricity consumption. Also, less energy used means a lesser price tag at the end of the month on energy bills, which is something everyone loves! Another double suction impeller centrifugal pump key benefit is that if you manage the impeller clearance well, this will reduce the wear of the pump, and the pump will work better for long time.

Why It Is Necessary To Adjust Impeller Clearance

The pump is running at its peak by finely tuning the clearance between impeller and casing. That means it can move water better and pump at higher flow rates. A well working pump is ultimately more reliable and helps avoid issues stemming from inefficiency. When everything goes right, it can be a big step up for pump efficiency and performance.

Conclusion

To summarize, taking measures to optimize impeller clearance could have a significant double suction impeller impact on the hydraulic performance of a submersible vertical turbine pumps. Optimising the gap between the impeller and the casing means the pump works faster, uses less energy, and lasts longer. So, the next time you see a submersible pump working tirelessly to bring water to the surface, just think about how critical that impeller clearance is in making it all happen! For all your pump optimization needs, trust Credo, and remember a happy pump is a well-maintained pump!

Comments

Post a Comment